STEEL SLAG ROAD TECHNOLOGY

STEEL SLAG ROAD TECHNOLOGY FOR SUSTAINABLE GREEN ROADS

Steel Slag Road Technology is developed by CSIR-Central Road Research Institute New-Delhi to facilitate utilization of waste steel slag as substitute of natural aggregates in road construction. On the directives of Niti Aayog under the major R&D project sponsored by Ministry of Steel along with four major steel industries namely Arcellor Mittal Nippon Steel India, TATA Steel, Rashtriya Ispat Nigam Limited and JSW Steel to CSIR-Central Road Research Institute, customized steel slag valorisation technologies are developed to convert raw steel slag as ” Processed Steel Slag Aggregates” for road making.

MAJOR STEEL SLAG ROAD PROJECT ACROSS INDIA

1. Surat, Gujarat

INDIA’S FIRST STEEL SLAG ROAD SECTION CONNECTING NH-6 to HAZIRA PORT

India’ first steel slag road connecting NH-6 to Hazira Port was built in April 2022 under CSIR-CRRI technological guidance using processed EAF steel slag aggregates in all layers of flexible pavement. Around 1 lakh tonne processed EAF steel slag aggregates are developed at Arcelor Mittal Nippon Steel India Limited, Hazira plant and utilized as 100% substitute of natural aggregates in subgrade, granular sub-base, base course and bituminous layers of flexible pavement. This 1 km long six lane bituminous road is designed for 100 MSA design traffic for 20-year design life and built with 32 % reduced thickness in comparison to prescribed thickness in IRC: 37:2018 for 100 MSA Design traffic and 8 % CBR subgrade.

Inauguration of Hazira Steel Slag Road by Hon’ble Union Minister of Steel Shri R.C.P. Singh in June 2022

2. Dolvi Mumbai, Maharashtra

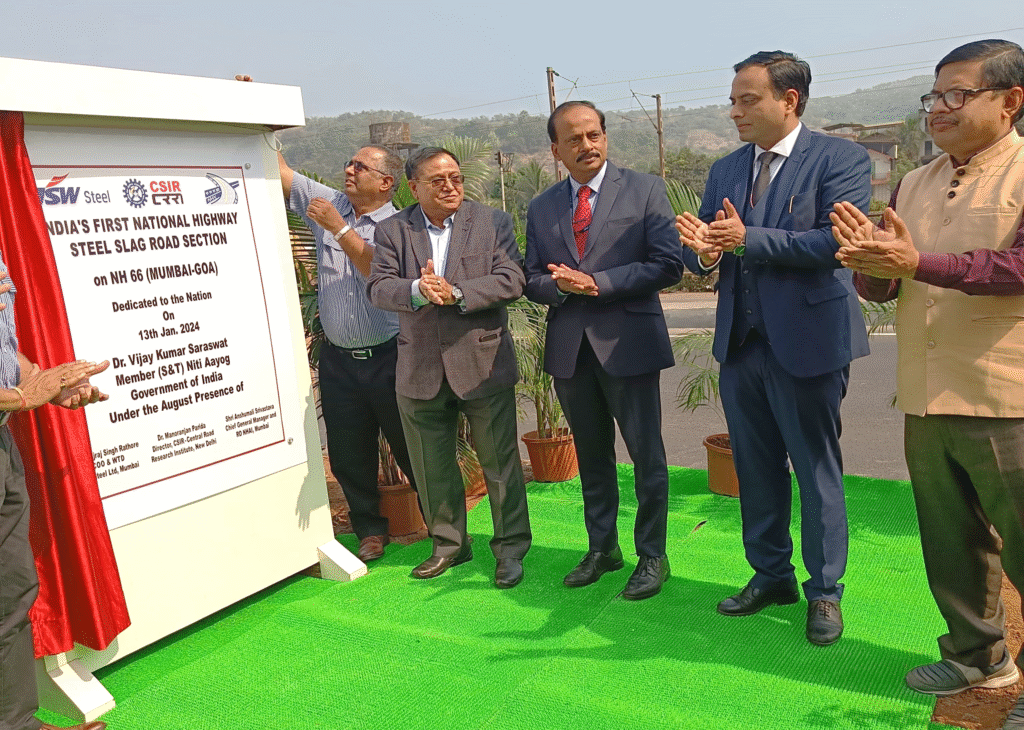

INDIA’S FIRST NATIONAL HIGHWAY STEEL SLAG ROAD SECTION ON NH-66 (Mumbai-Goa National Highway)

India’ first national highway steel slag road section on NH-66 was built in June 2023 under CSIR-CRRI technological guidance using processed CONARC steel slag aggregates in all layers of flexible and rigid pavement. Around 80000 tons Processed CONARC steel slag aggregates were developed at JSW Steel, Dolvi plant and utilized as 100% substitute of natural aggregates in subgrade, granular sub-base, base course and wearing course i.e. bituminous layers and PQC and DLC layers of flexible and rigid pavement. Bituminous road section was designed for 75 MSA design traffic and built with 28 % reduced thickness in comparison to conventional asphalt road thickness prescribed in IRC:37 for 62 MSA design traffic

Aerial View of Cement Concrete and Bituminous Steel Slag Road Section on NH-66 Dolvi, Mumbai

3. Ziro Valley, Arunachal Pradesh

STEEL SLAG ROAD BRO PROJECT ARUNACHAL PRADESH

Steel Slag Road section built by Border Road Organization on Joaram-Koloriang Road in Arunachal Pradesh. This 1 km long steel slag road section is constructed by Border Road Organization Project Arunank Division under CSIR- Central Road Research Institute, New-Delhi, technological guidance in Dec. 2022 using processed BOF steel slag aggregates supplied by TATA Steel Jamshedpur plant. Around 1200 MT processed steel slag aggregates were transported via. Railway rack from Jamshedpur to Itanagar and further from Itanagar to project site near ziro valley via road. Bituminous concrete layers of 40 mm thickness were constructed using processed BOF Steel Slag Aggregates.

Glimpse of Steel Slag Road Section Built at Ziro, Arunachal Pradesh by BRO

4. Ranchi-Jamshedpur-Kolkata

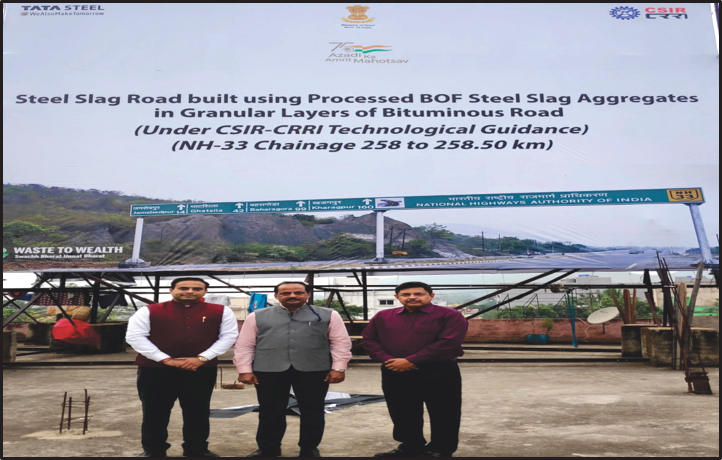

STEEL SLAG ROAD NH-33 RANCHI-JAMSHEDPUR-KOLKATA

Under CSIR-CRRI technological guidance, processed BOF Steel slag aggregates were successfully utilized in the construction of L.H.S. carriageway of six lane National Highway of NH-33 Ranchi- Jamshedpur-Kolkata section in 2016. Processed BOF steel slag aggregates were developed at TATA Steel Jamshedpur plant under CRRI technical guidance through accelerated weathering technique by carrying out alternate wetting and drying of BOF slag aggregates. These aggregates were further utilized as 100% substitute of natural aggregates in base course and sub-base course from chainage 258.000 to 258.500 of Jamshedpur to Mahulia section of NH-33 under CRRI technological supervision. Infield evaluation of WMM and GSB layers were carried out by CSIR-CRRI team to determine the field density, in-situ permeability, material characteristic of base course and sub-base course layers

BOF Steel Slag Aggregates in GSB and WMM Layers of NH-33 on Natural Soil Embankment

5. Adani Port Surat, Gujarat

INDIA’S FIRST STEEL SLAG PORT ROAD

The world’s first coastal steel slag road is constructed by Adani Ports and SEZ at Hazira port under CSIR-CRRI technological guidance using Arcelor Mittal Nippon Steel India processed EAF steel slag. This project is a true testament of green infrastructure development by transforming waste to wealth

Bituminous Steel Slag Road Section at Adani Port Hazira, Surat

HEADLINES.......

© 2025. All rights reserved